Heavy metal fabrication is a complex yet indispensable industry demanding deep knowledge of shaping techniques, rigorous safety standards, and strategic practices for efficiency. Key aspects include proper equipment maintenance, adherence to health and environmental regulations, advanced machinery like laser cutters and CNCs, lean manufacturing principles, and material selection based on project needs. Advanced technologies, including automation and digital tools like CAD software, are revolutionizing the sector by enhancing safety and productivity, fostering a safer, more sustainable future in heavy metal fabrication.

Efficient and safe heavy metal fabrication is a cornerstone of modern industry, driving innovation across diverse sectors. Understanding the intricacies of this process—from processes and safety protocols to material choices and advanced technologies—is paramount for optimizing productivity while ensuring worker well-being. This article explores these key aspects, providing insights into best practices for industrial metal fabrication, with a focus on enhancing efficiency and maintaining the highest safety standards.

- Understanding Heavy Metal Fabrication: Processes and Safety Protocols

- Optimizing Efficiency in Industrial Metal Fabrication Shops

- Choosing the Right Materials and Their Impact on Safety and Quality

- Advanced Technologies and Their Role in Enhancing Safety and Productivity

Understanding Heavy Metal Fabrication: Processes and Safety Protocols

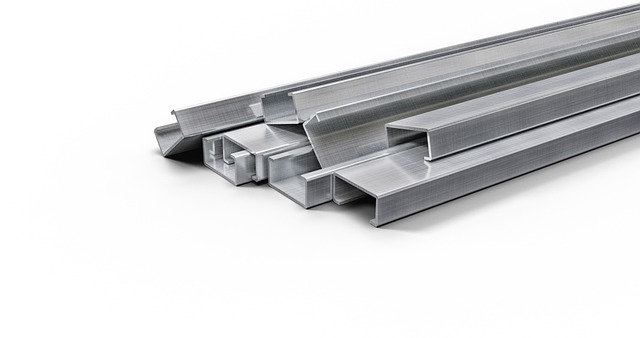

Heavy metal fabrication, a process that involves shaping and forming various metals into desired structures, is a complex yet crucial industry. It encompasses a range of techniques, from cutting and shearing to welding, bending, and finishing. Each step demands precision and adherence to safety protocols, especially considering the potential risks associated with heavy machinery and hazardous materials.

Understanding these processes is key to ensuring efficiency and worker safety. Rigorous training, regular equipment maintenance, and implementing robust health and safety standards are essential. Personal protective equipment (PPE) plays a vital role in shielding workers from metal fragments, burns, and other accidents. Additionally, proper ventilation and adherence to environmental regulations are critical aspects of responsible heavy metal fabrication practices.

Optimizing Efficiency in Industrial Metal Fabrication Shops

In the realm of heavy metal fabrication, optimizing efficiency is paramount to stay competitive in an ever-evolving industry. Shops can significantly enhance productivity by implementing strategic practices and investing in modern technology. Automation plays a pivotal role; robotic arms and computer-aided design (CAD) software streamline processes, reducing manual labor and minimizing errors. Additionally, integrating advanced machinery like laser cutters and CNC (Computer Numerical Control) machines allows for precise, high-speed cutting and shaping of metal, thus increasing throughput.

Regular maintenance and upgrade of equipment are essential to maintaining efficiency. Well-maintained tools ensure smooth operations, prevent downtime, and prolong the lifespan of machinery. Moreover, staying abreast of industry trends and adopting innovative techniques can further boost productivity. For instance, implementing lean manufacturing principles, such as just-in-time inventory management, helps minimize waste and maximizes resource utilization in heavy metal fabrication shops.

Choosing the Right Materials and Their Impact on Safety and Quality

Choosing the right materials is a cornerstone of efficient and safe heavy metal fabrication. Each metal has distinct properties, affecting everything from strength and durability to workability and cost. For instance, while steel offers superior strength and resistance, its hardness can make it challenging to weld or cut without specialized equipment. Aluminum, on the other hand, is lighter and more easily workable but may compromise structural integrity in high-stress applications.

Selecting materials that align with project requirements ensures not only optimal performance but also mitigates safety risks. Using appropriate metals reduces the likelihood of failure, especially in critical components where even a minor defect can have catastrophic consequences. This careful material choice, combined with meticulous fabrication processes, is key to delivering high-quality, safe, and reliable products in the industrial metal fabrication sector.

Advanced Technologies and Their Role in Enhancing Safety and Productivity

In the realm of heavy metal fabrication, advanced technologies are transforming the industry by enhancing safety and productivity. Automated systems and robotics are increasingly being adopted to handle hazardous tasks, reducing human error and exposure to risks like extreme temperatures, heavy machinery, and toxic materials. These innovations not only safeguard workers but also streamline production processes, allowing for faster turnaround times and improved efficiency.

Moreover, digital tools such as computer-aided design (CAD) software and advanced material handling systems play a pivotal role in the precision and quality of metal fabrication. CAD enables designers to create detailed blueprints, minimizing errors in measurement and specifications. Material handling systems, on the other hand, optimize the movement of materials through the production line, reducing waste and maximizing resource utilization. These technological advancements collectively contribute to a safer, more productive, and ultimately, more sustainable heavy metal fabrication process.

Heavy metal fabrication is a complex yet essential process that demands a balance between efficiency and safety. By understanding the various processes, implementing optimized protocols, and adopting advanced technologies, industrial shops can enhance productivity while ensuring worker well-being. Choosing the right materials and maintaining strict safety standards are pivotal to achieving high-quality outcomes without compromising on safety measures. This holistic approach to heavy metal fabrication ensures that modern workshops stay competitive, efficient, and safe in today’s market.