The article discusses the essential role of Industrial Metal in crafting durable and precise machinery components, highlighting the importance of Functional Metalwork tailored to specific operational needs. It details the advanced Heavy Metal Fabrication processes that transform raw metals into intricate parts, ensuring they adhere to high-quality standards necessary for structural integrity and safety under demanding conditions. Advancements in Industrial Design, coupled with Custom Metal solutions, are pushing the boundaries of machinery applications across various industries by creating utility metalwork components that enhance performance and durability. These tailored metals are engineered to perform exceptionally in both harsh and less challenging industrial environments. The article concludes by emphasizing that Utility Metalwork is integral to optimizing machinery for peak operational performance, which in turn boosts overall productivity within the industrial sector. It underscores the synergy between practicality and artistic expression in this specialized field, with a focus on meeting exacting standards for bespoke industrial metal solutions.

exploration of high-quality metalwork’s critical role in machinery and equipment design and construction is essential. This article delves into the robust world of Industrial Metal, showcasing its strength and precision in machinery construction. We will examine the intricate heavy metal fabrication techniques that blend artistry with functionality, ensuring structural metal contributes to the durability and safety of equipment design. The importance of tailored solutions through Custom Metal applications is highlighted, revealing their indispensable utility within industrial design. Join us as we explore how these metallic marvels power the heart of machines and systems globally.

- Unveiling the Strength and Precision of Industrial Metal in Machinery Construction

- The Artistry Behind Functional Metalwork: A Glimpse into Heavy Metal Fabrication Techniques

- Structural Metal's Role in Ensuring Durability and Safety in Equipment Design

- Tailoring Excellence: The Process and Benefits of Custom Metal Solutions for Industrial Applications

Unveiling the Strength and Precision of Industrial Metal in Machinery Construction

In the realm of industrial machinery and equipment, the role of high-quality metalwork cannot be overstated. Industrial Metal stands as a testament to robustness and precision, integral to the construction of machinery that endures the rigors of various industries. The strength of these metals is not their sole attribute; equally important is their ability to provide functionality through customized designs that cater to specific operational demands. Functional Metalwork, crafted with meticulous attention to detail, ensures that each component within the machinery operates seamlessly, contributing to the overall efficiency and longevity of the equipment. The process of heavy metal fabrication employs advanced techniques to transform raw metal into intricate parts, adhering to stringent quality standards that are indispensable for structural integrity and safety in high-stress environments.

Advancements in industrial design continue to push the boundaries of what is possible with Custom Metal solutions, leading to innovative applications across a multitude of sectors. These bespoke metal pieces are not mere replacements or enhancements but are engineered to optimize utility and performance, often exceeding the expectations of their users. The versatility of these metals means they can be tailored for use in environments ranging from the most extreme industrial conditions to more benign settings, all while maintaining exceptional durability and functional excellence. Utility Metalwork, therefore, is a critical component in the continuous improvement and evolution of machinery and equipment, ensuring that each part performs at its peak, thereby driving productivity and operational success.

The Artistry Behind Functional Metalwork: A Glimpse into Heavy Metal Fabrication Techniques

Crafting high-quality functional metalwork is an intricate blend of industrial design and precision engineering. The process begins with selecting the right industrial metal, often steel or aluminum alloys, for their durability and malleability in heavy metal fabrication. Skilled artisans employ a variety of techniques to transform these raw materials into structural metal components that are both robust and aesthetically pleasing. These techniques range from traditional welding and bending to advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) processes, ensuring each custom metal piece adheres to stringent specifications for utility metalwork. The end result is a testament to the artistry behind functional metalwork, where each structural metal element not only withstands the rigors of industrial applications but also contributes to the cohesive design and functionality of machinery and equipment.

In the realm of heavy metal fabrication, the synergy between art and utility is particularly evident. The process demands a deep understanding of both the material properties of the industrial metal used and the intended application. This knowledge enables fabricators to innovate within the constraints of structural metal requirements, leading to bespoke solutions that are tailored to specific operational needs. The precision and attention to detail required in this craft ensure that each piece of custom metalwork serves its functional purpose while also embodying a level of sophistication that belies its industrial nature. This harmonious blend of practicality and artistry is what distinguishes exceptional utility metalwork from the ordinary, making it indispensable in various sectors ranging from construction to automotive manufacturing.

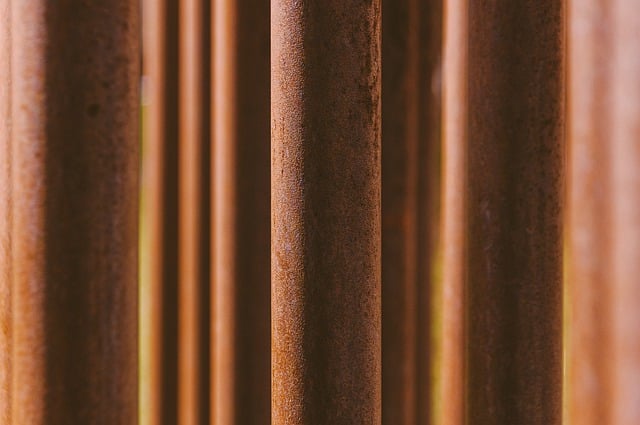

Structural Metal's Role in Ensuring Durability and Safety in Equipment Design

In the realm of industrial design, the role of high-quality structural metal cannot be overstated. Industrial Metal plays a pivotal part in constructing machinery and equipment that withstand the rigors of heavy use. The resilience of these materials ensures durability, allowing for safe operation under pressure. Engineers meticulously apply functional metalwork principles to create custom metal solutions tailored to specific utility needs. This bespoke approach to heavy metal fabrication is crucial in designing equipment that meets exacting standards, thereby enhancing the overall safety and longevity of the machinery.

The selection of the right structural metal is a critical aspect of industrial equipment design. These metals are engineered to endure extreme conditions, offering resistance to wear, corrosion, and environmental factors. The integration of advanced alloys in heavy metal fabrication processes enables the creation of parts with precise tolerances, which is essential for the smooth functioning of complex machinery. This attention to detail in the functional metalwork aspects ensures that each component contributes to the structural integrity and safety of the entire system, thereby minimizing the risk of failure during operation.

Tailoring Excellence: The Process and Benefits of Custom Metal Solutions for Industrial Applications

In the realm of industrial manufacturing, the demand for high-quality metal solutions tailored to specific applications is paramount. Custom metal fabrication stands at the forefront, offering functional metalwork that precisely meets the unique requirements of machinery and equipment. This bespoke approach ensures that each component, from heavy metal fabrication to structural metal elements, is engineered with precision and resilience. The process begins with a thorough analysis of the industrial design specifications, where engineers collaborate closely with clients to understand the exact demands of the utility metalwork needed. This collaboration not only optimizes performance but also fosters innovation, leading to solutions that enhance efficiency, durability, and safety within the industrial environment.

The benefits of investing in custom metalwork are manifold. It allows for greater flexibility in design, enabling machinery to be more ergonomic and efficient. By adopting a tailored approach, structural metal components can be fine-tuned to withstand the specific stresses and strains encountered in their operational setting. This not only extends the lifespan of the equipment but also ensures that it operates at peak performance. Moreover, the integration of industrial metal solutions into the design process from the outset results in a product that is both functional and aesthetically aligned with the overall industrial design ethos. The end result is a harmonious blend of form and function, where every metal element serves a purpose and contributes to the seamless operation of the machinery.

In conclusion, the critical role of high-quality industrial metal in machinery and equipment design cannot be overstated. From the artistry of functional metalwork in heavy metal fabrication to the structural integrity provided by metal solutions in industrial design, these components are indispensable for ensuring durability, safety, and operational efficiency. Custom metalwork not only caters to specific demands but also elevates the functionality of equipment across various industries. As a testament to its importance, the adoption of tailored, high-quality utility metalwork stands as a pivotal advancement in maintaining competitive edge and reliability in today’s rapidly evolving technological landscape. Embracing these sophisticated approaches in industrial metal application underscores the commitment to excellence in machinery performance and longevity.