Heavy metal fabrication is a specialized process using advanced techniques and machinery to transform raw metals like steel, aluminium, and copper into precise structures for diverse industries. Expert welders employ methods such as TIG and MIG welding, followed by heat treatment and surface preparation, to create durable components exceeding specifications for manufacturing, automotive, aerospace, infrastructure, and energy sectors, ensuring structural integrity, longevity, and enhanced productivity.

In the realm of industrial metal projects, heavy metal fabrication forms the crucible where strength, durability, and precision are forged. This comprehensive guide delves into the core processes that underpin this demanding sector, exploring expert welding and assembly techniques essential for its success. From understanding the foundational principles of heavy metal fabrication to mastering specialized welding methods (MIG, TIG, Arc) and meticulous assembly strategies, we unravel the tapestry of best practices ensuring structural integrity and optimal efficiency across diverse industries.

- Understanding Heavy Metal Fabrication: The Foundation of Industrial Projects

- – Definition and scope of heavy metal fabrication

- – Key industries relying on this process

- Expert Welding Techniques for Unparalleled Strength and Durability

Understanding Heavy Metal Fabrication: The Foundation of Industrial Projects

Heavy metal fabrication forms the bedrock of numerous industrial projects, requiring precise techniques and expert skillsets to bring designs to life. This intricate process involves the manipulation of robust metals like steel, aluminium, and copper to create complex structures. From constructing massive industrial machinery to crafting intricate automotive components, heavy metal fabrication is a cornerstone of modern industry.

Specialised welding and assembly techniques are pivotal in this domain. Skilled artisans fuse metals together using arc welding, laser cutting, and other advanced technologies to ensure structural integrity and quality. Assembly processes involve meticulous attention to detail, aligning parts with sub-millimetre precision to create robust, long-lasting frameworks. This foundation of expertise ensures that industrial projects not only meet but exceed specifications, contributing to the efficiency and longevity of various sectors, from manufacturing to infrastructure development.

– Definition and scope of heavy metal fabrication

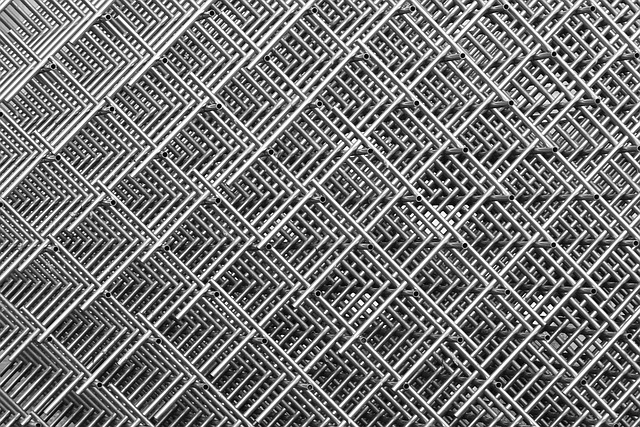

Heavy Metal Fabrication refers to the process of creating intricate metal structures and components through specialized techniques, primarily involving cutting, bending, welding, and assembling large pieces of metal. This diverse field encompasses a wide range of industrial projects, from constructing heavy machinery and equipment to manufacturing structural elements for buildings and bridges. The scope includes both custom designs and mass-produced parts, requiring precision, strength, and durability.

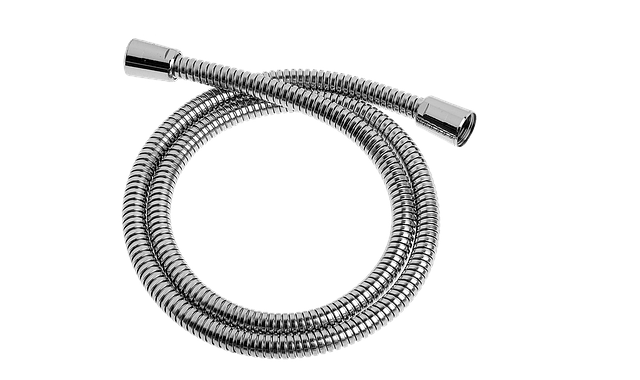

It involves the manipulation of raw metal sheets, plates, and bars to create complex shapes and forms. Skilled fabricators use advanced machinery, such as lasers, water jets, and computer numerical control (CNC) machines, for accurate cutting and forming. Assembly often follows fabrication, where various components are joined together using techniques like welding, bolting, or riveting, ensuring structural integrity and functionality. This meticulous process is crucial in industries demanding robust and reliable metal structures.

– Key industries relying on this process

The expertise in welding and assembly is pivotal for several industries that rely heavily on heavy metal fabrication. These include aerospace, where precise welding techniques are crucial for constructing aircraft components that withstand extreme conditions, and automotive manufacturing, which demands robust and reliable assembly processes to create high-performance vehicles. Additionally, the construction sector benefits immensely from these skills, as they are essential for erecting structural steel frameworks and fabricating complex metal structures for bridges, skyscrapers, and other infrastructure projects.

Moreover, industries such as energy generation, mining, and machinery manufacturing heavily invest in expert welding and assembly to produce durable equipment and systems. In these sectors, the ability to fuse metals reliably is not just about functionality; it’s also a matter of safety and efficiency. Well-executed welding ensures that machinery runs smoothly, reduces downtime, and enhances overall productivity across diverse industrial applications.

Expert Welding Techniques for Unparalleled Strength and Durability

In the realm of heavy metal fabrication, expert welding techniques are paramount for achieving unparalleled strength and durability in industrial projects. Skilled welders employ advanced methods such as precision TIG (Tungsten Inert Gas) welding and robust MIG (Metal Inert Gas) welding to forge robust bonds between metal components. These techniques ensure precise alignment and consistent fusion, resulting in structures that can withstand extreme forces and environmental conditions.

Beyond methodical application, expert welders understand the critical role of post-welding treatments. Heat treatment, stress relief, and surface preparation are integral steps that enhance the final product’s performance. By carefully managing these processes, they produce metal assemblies with superior mechanical properties, ensuring longevity and reliability in demanding industrial applications.

Heavy metal fabrication is a specialized process that underpins numerous industrial sectors, demanding precise welding and assembly techniques to ensure structural integrity. For projects requiring exceptional strength and longevity, experts in this field are indispensable. By mastering various welding methods, they create durable solutions tailored to specific industry needs, be it for construction, automotive, or aerospace applications. This level of expertise ensures that metal structures not only withstand intense conditions but also contribute to the success of complex industrial endeavors.