In industrial metal projects, understanding intricate material science is key for successful welding and assembly. From heavy-duty machinery frames to custom components, functional metalwork demands materials chosen for strength and durability. Heavy metal fabrication techniques cater to complex shapes, while utility metalwork uses lighter gauge materials. Custom metal designs require a multidisciplinary approach involving designers, engineers, and welders to meet industry standards. Advanced manufacturing techniques enhance accuracy and consistency in structural integrity across diverse conditions. Skilled artisans transform raw materials into custom metal components for demanding industries like manufacturing and healthcare, driving innovation in industrial metal design.

In the realm of industrial metal projects, precision and durability are paramount. From massive structures to intricate components, understanding the unique properties of various industrial metals and their requirements is crucial for successful fabrication. Heavy metal fabrication demands expertise in welding and assembly techniques that ensure structural integrity and longevity.

This guide explores functional metalwork, delving into custom metal project needs, from material selection to advanced assembly methods. Discover how expert craftsmanship revolutionizes industrial design by delivering robust, tailored solutions for diverse applications.

- Understanding Industrial Metal Projects: Materials and Requirements

- – Types of industrial metal and their unique properties

- – Key considerations for structural integrity in heavy metal fabrication

- – Importance of functional metalwork in industrial design

Understanding Industrial Metal Projects: Materials and Requirements

Understanding the intricacies of industrial metal projects is paramount when it comes to successful welding and assembly. These projects often involve complex structures demanding precision and robustness, from heavy-duty machinery frames to intricate industrial equipment components. The primary focus lies in functional metalwork, where materials must be chosen based on their strength, durability, and compatibility with the project’s specific requirements.

Industrial metal fabrication encompasses a wide range of applications, from structural metal used in construction to utility metalwork for various industrial processes. Custom metal designs are also prevalent, catering to unique client needs. The success of these projects relies heavily on expert knowledge of materials science, ensuring the right metal types are selected for each component, considering factors like corrosion resistance, temperature tolerance, and mechanical properties to guarantee optimal performance in diverse environments.

– Types of industrial metal and their unique properties

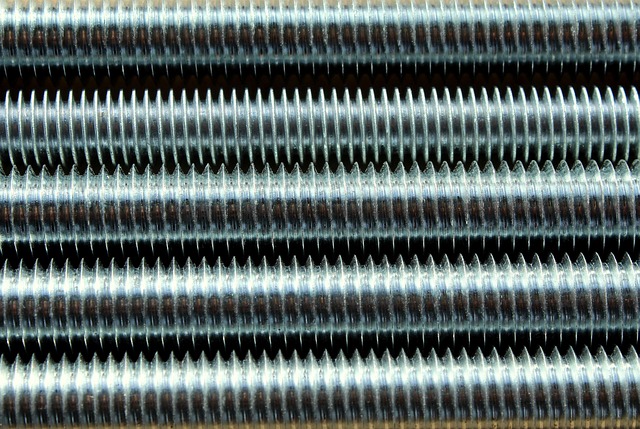

Industrial metal projects encompass a diverse range of materials, each with its own distinct properties and applications. From structural metal like steel, known for its strength and versatility, to functional metalwork alloys designed for specific tasks, such as corrosion resistance or high-temperature performance, understanding these metals is key. Heavy metal fabrication, involving thicker sections and complex shapes, requires specialized techniques to ensure precision and integrity. Conversely, utility metalwork involves lighter gauge materials used in various components and assemblies.

In the realm of industrial design, custom metalwork plays a pivotal role, allowing for unique solutions tailored to specific project needs. This includes intricate designs, precise tolerances, and specific finishes that enhance both functionality and aesthetics. Whether focusing on structural integrity or aesthetic appeal, skilled welders and assembly specialists are essential. They bring expertise in handling these varied metals, ensuring every component meets the highest standards of quality and safety across diverse industrial applications.

– Key considerations for structural integrity in heavy metal fabrication

When it comes to heavy metal fabrication, ensuring structural integrity is paramount. Key considerations include selecting the right materials for the specific project needs, adhering to strict quality control measures during every stage of production, and implementing robust design principles that account for stresses and loads. For industrial metal projects, where functionality and durability are paramount, experts emphasize the importance of detailed engineering plans that integrate both aesthetic and structural elements seamlessly.

In the realm of custom metal fabrication, especially for utility metalwork applications, achieving superior structural integrity requires a multidisciplinary approach. This involves close collaboration between designers, engineers, and skilled welders who bring expertise in creating intricate, complex pieces that meet stringent industry standards. The integration of advanced manufacturing techniques, such as precision cutting and computer-aided design (CAD), further enhances the accuracy and consistency of functional metalwork, ensuring the final product not only looks impressive but also stands strong under various conditions.

– Importance of functional metalwork in industrial design

In the realm of industrial design, functional metalwork serves as the backbone, enabling robust and efficient structures. Heavy metal fabrication techniques are essential for crafting structural metal components that withstand extreme conditions, from harsh environments to intense workloads. These custom metal pieces form the very foundation of various machines, buildings, and infrastructure, ensuring their longevity and reliability.

Industrial metal projects demand precision and expertise in utility metalwork. Skilled welders and assemblers play a pivotal role in transforming raw materials into intricate, functional parts. Their artistry ensures that every joint is secure, every connection seamless, and each piece aligns perfectly with the overall industrial design. This meticulous process guarantees the structural integrity of final products, be it a massive manufacturing plant or a delicate medical device, thereby fostering innovation within the industrial landscape.

In conclusion, expert welding and assembly are paramount for successful industrial metal projects. Understanding the unique properties of various industrial metals, prioritizing structural integrity in heavy metal fabrication, and integrating functional metalwork into industrial design are essential components of this process. Custom metal solutions tailored to specific utility metalwork requirements ensure robust and reliable outcomes. For businesses navigating these complex tasks, partnering with professionals who excel in both welding and assembly can be a game-changer, revolutionizing their approach to industrial metal projects.